鶴崗AH/HH slurry pump

訂購電話:166-0318-1010

發(fā)布時間:2019-06-25 10:21:04

產(chǎn)品說明:

The AH/HH slurry pump refers to a kind of machinery that increases the energy of the solid-liquid mixed medium by means of the centrifugal force (the rotation of the pump's impeller), and it is a device that converts electrical energy into the k

The AH/HH slurry pump refers to a kind of machinery that increases the energy of the solid-liquid mixed medium by means of the centrifugal force (the rotation of the pump's impeller), and it is a device that converts electrical energy into the kinetic energy and potential energy of the medium. It is mainly applicable to industries such as mining, power plants, dredging, metallurgy, chemical engineering, building materials, and petroleum.

Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and gains energy, leaving the outer edge of the impeller at a high speed and entering the volute pump casing. In the volute pump casing, the liquid decelerates due to the gradual expansion of the flow passage, and part of the kinetic energy is converted into static pressure energy. Finally, it flows into the discharge pipeline at a relatively high pressure and is sent to the required place. When the liquid flows from the center of the impeller to the outer edge, a certain vacuum is formed at the center of the impeller. Since the pressure above the liquid level in the storage tank is greater than the pressure at the pump inlet, the liquid is continuously pressed into the impeller.

The following points should be noted during the maintenance of the slurry pump:

(1) The water pressure and water volume of the bearing should meet the specified requirements. Adjust the tightness of the packing at any time (or replace it), and do not cause slurry leakage at the shaft seal. And replace the shaft sleeve in a timely manner.

(2) When replacing the bearing, it is necessary to ensure that there is no dust in the bearing assembly and the lubricating oil is clean. Generally, the bearing temperature during the operation of the pump should not exceed 60-65°C, and the maximum should not exceed 75°C.

(3) Ensure the coaxiality of the motor and the pump, and ensure that the elastic pad in the coupling is complete and correct. Replace it in time after it is damaged.

(4) Ensure that the installation of the pump components and the pipeline system is correct, firm and reliable.

(5) Some components of the slurry pump are vulnerable parts. In daily use, pay attention to the wear situation of the vulnerable parts and repair or replace them in a timely manner. During the repair or replacement process of the vulnerable parts of the slurry pump, ensure correct assembly and reasonable clearance adjustment to avoid the occurrence of tight and rough friction.

(6) The suction pipeline system of the slurry pump must have no air leakage phenomenon. At the same time, pay attention to whether there is a blockage at the suction port during operation. The medium to be processed by the slurry pump mostly contains solid particles. Therefore, the grille placed in the pump sump should meet the requirements of the particles that the slurry pump can pass through, reducing the possibility of blockage caused by the entry of overly large particles or long fiber materials into the pump body.

Thank you very much for visiting and reading the above content! This piece of information is an introduction to the letter codes of commonly used submersible slurry pump models and basic knowledge. If you want to have a further understanding of this issue or want to purchase related products, please directly contact the customer service personnel of our company. You are welcome to consult at any time.

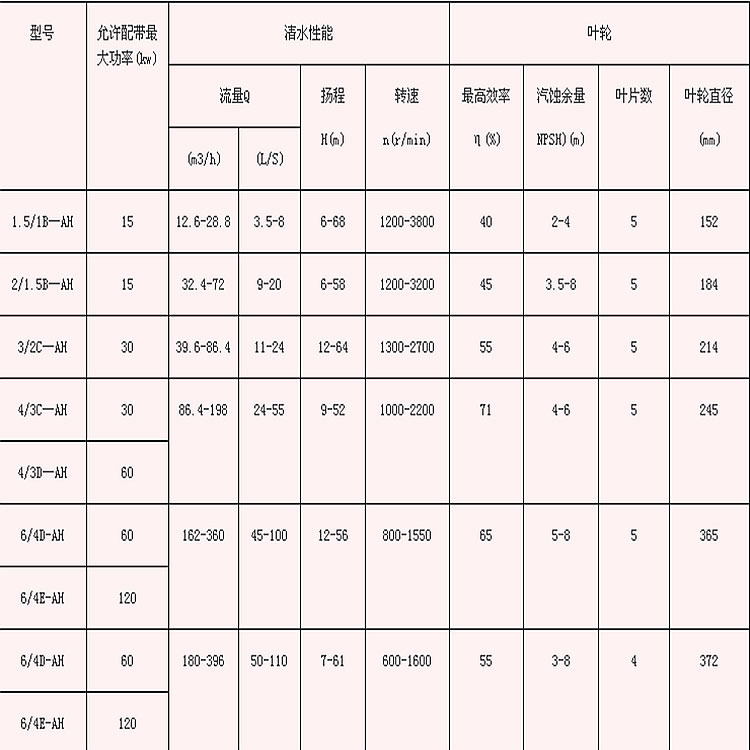

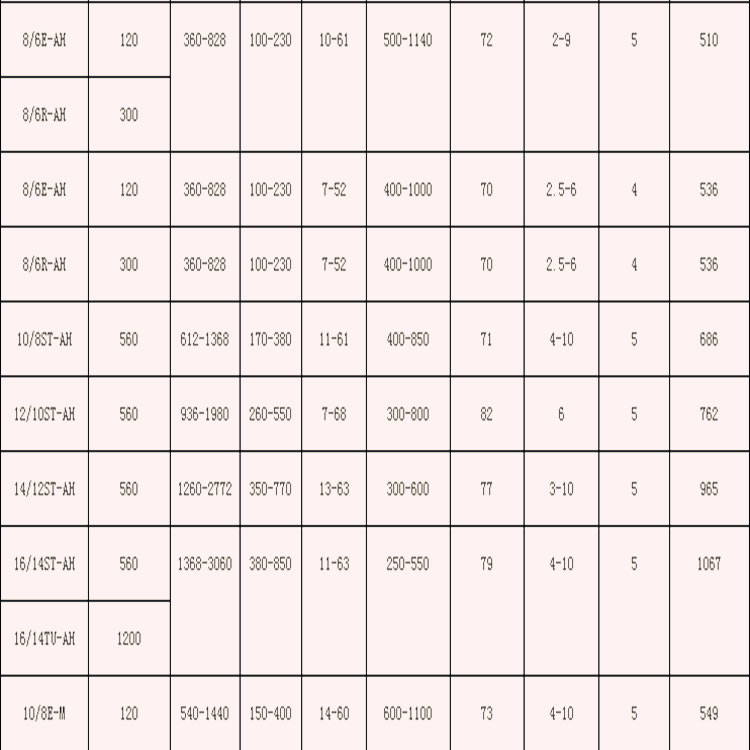

Due to the large number of product performance parameters, our company has only provided some of them. If you need more parameters, you can contact our company's technician at 182-3296-2233!

推薦資訊

地區(qū)產(chǎn)品

鶴崗slurry pump

- 鶴崗SP and SPR slurry pumps

- 鶴崗AH/HH slurry pump

- 鶴崗ZJ series slurry pumps

- 鶴崗ZJQ slurry pump

- 鶴崗ZJL Submerged Slurry Pump

- 鶴崗ZGB Slurry Centrifugal Pump

- 鶴崗Submerged slurry pump

- 鶴崗Horizontal slurry pump

- 鶴崗Foam pump

- 鶴崗Submersible slurry pump

鶴崗泥漿泵

- 鶴崗PN mud pump

- 鶴崗PNL Mud Pump

- 鶴崗NL mud pump

- 鶴崗Marine mud pump

- 鶴崗Submersible mud pump

- 鶴崗Submerged mud pump

- 鶴崗Petroleum mud pump

鶴崗化工泵

- 鶴崗化工流程泵

- 鶴崗化工循環(huán)泵

- 鶴崗耐鹽酸離心泵

- 鶴崗IH型化工泵

- 鶴崗氟塑料化工泵

- 鶴崗襯氟化工離心泵

- 鶴崗FZB氟塑料自吸泵

- 鶴崗臥式化工離心泵

- 鶴崗不銹鋼化工離心泵

- 鶴崗耐腐蝕不銹鋼離心泵

- 鶴崗無泄漏襯氟塑料離心泵

鶴崗壓濾機入料泵

- 鶴崗SYA Feed Pump for Filter Press

- 鶴崗ZJE Type Feed Pump for Filter Press

- 鶴崗ZJW Feed Pump for Filter Press

- 鶴崗plate and frame filter press

- 鶴崗environmental protection filter press pump

- 鶴崗Specialized Pump for Coal Washing Plants

- 鶴崗Filter Press Feed Pump

- 鶴崗Plate and Frame Filter Press

鶴崗管道泵

聯(lián)系我們

24小時服務熱線166-0318-1010- 聯(lián)系人: 張經(jīng)理

- 公司地址: 安平縣安平鎮(zhèn)后張莊村村北1000米處