鶴崗ZJQ slurry pump

訂購電話:166-0318-1010

發(fā)布時間:2019-06-25 15:38:25

產(chǎn)品說明:

The ZJQ submersible sand suction pump has its motor and water pump operating underwater coaxially. The flow-through components of this pump are made of high-chromium alloy wear-resistant materials, which endow it with good wear resistance and a large flow

The ZJQ submersible sand suction pump has its motor and water pump operating underwater coaxially. The flow-through components of this pump are made of high-chromium alloy wear-resistant materials, which endow it with good wear resistance and a large flow passage. It is suitable for transporting media such as sand and sediment containing relatively large solid particles, ore pulp, coal pulp, and sand and gravel... This series of products is designed and manufactured by absorbing advanced technologies. The unique sealing device can effectively balance the pressure inside and outside the oil chamber, maximizing the protection of the reliability of the mechanical seal. The motor is equipped with multiple protection measures such as overheating protection and water inlet detection protection, enabling it to operate safely for a long time under harsh working conditions. The front mixing impeller of the water pump can impact the deposited sediment into a high-concentration turbulent flow, allowing the water pump to achieve high-concentration sediment suction without the need for auxiliary devices.

II. Product Features

III. Usage Conditions

Maintenance and Upkeep

Please note that in the text above, where it says "not less than [a certain value] meters", you need to fill in the specific minimum submergence depth value according to the actual situation. If you want to translate this text into other languages or have other requirements, you can continue to ask me.

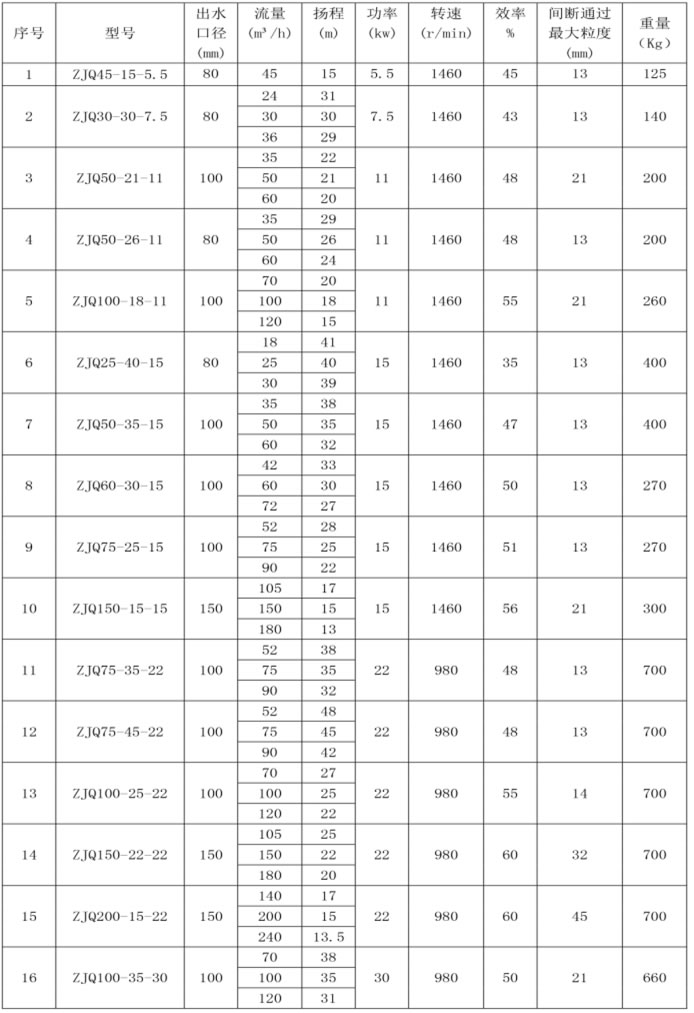

Due to the large number of performance parameters, our company only provides some of them. If you need more detailed parameters, please contact our company's technician at 18232962233.

推薦資訊

地區(qū)產(chǎn)品

鶴崗slurry pump

- 鶴崗SP and SPR slurry pumps

- 鶴崗AH/HH slurry pump

- 鶴崗ZJ series slurry pumps

- 鶴崗ZJQ slurry pump

- 鶴崗ZJL Submerged Slurry Pump

- 鶴崗ZGB Slurry Centrifugal Pump

- 鶴崗Submerged slurry pump

- 鶴崗Horizontal slurry pump

- 鶴崗Foam pump

- 鶴崗Submersible slurry pump

鶴崗泥漿泵

- 鶴崗PN mud pump

- 鶴崗PNL Mud Pump

- 鶴崗NL mud pump

- 鶴崗Marine mud pump

- 鶴崗Submersible mud pump

- 鶴崗Submerged mud pump

- 鶴崗Petroleum mud pump

鶴崗化工泵

- 鶴崗化工流程泵

- 鶴崗化工循環(huán)泵

- 鶴崗耐鹽酸離心泵

- 鶴崗IH型化工泵

- 鶴崗氟塑料化工泵

- 鶴崗襯氟化工離心泵

- 鶴崗FZB氟塑料自吸泵

- 鶴崗臥式化工離心泵

- 鶴崗不銹鋼化工離心泵

- 鶴崗耐腐蝕不銹鋼離心泵

- 鶴崗無泄漏襯氟塑料離心泵

鶴崗壓濾機入料泵

- 鶴崗SYA Feed Pump for Filter Press

- 鶴崗ZJE Type Feed Pump for Filter Press

- 鶴崗ZJW Feed Pump for Filter Press

- 鶴崗plate and frame filter press

- 鶴崗environmental protection filter press pump

- 鶴崗Specialized Pump for Coal Washing Plants

- 鶴崗Filter Press Feed Pump

- 鶴崗Plate and Frame Filter Press

鶴崗管道泵

聯(lián)系我們

24小時服務熱線166-0318-1010- 聯(lián)系人: 張經(jīng)理

- 公司地址: 安平縣安平鎮(zhèn)后張莊村村北1000米處